Belt Construction

Flat woven endless belts are used on a wide variety of equipment for many different applications and specific end uses. Their uses vary from extremely sensitive drive applications, such as instrumentation, recording devices and sensitive weigh-pan conveying applications, to light and medium duty uses, such as currency and check transports, film transports, paper handling and vacuum transporting sections of business and office machinery, all the way up to high speed grinding, spindle drives, wire drawing applications, woodworking equipment and textile machinery drives. The variety of possible applications require an extremely wide range of specific physical properties that will enable each belt to perform its task continuously, with good reliability throughout its life.

Features:

Belt Types

With the combination of various yarn types and multiple styles of weaving, we have a plethora of belting possibilities. Our most common style of belts are referred to as Stable, Semi-Stable, Semi-Stretch, Stretch.

STABLE BELTS

Used on drives having some means of belt tensioning, such as a movable pulley location or an external tensioning pulley, either spring-loaded or locked in place after tensioning of the belt is completed.

These belts are typically used on individual belt drives or group drives where each belt is separately tensioned. Applications include high-speed power transmission, woodworking machinery, card readers, sorters, and printing machinery.

SEMI-STABLE BELTS

Allow the use of multiple belts with common take-up, or length adjustment. They can be used on wide belt conveying and on applications requiring good edge wear resistance for flanged or guided tracking. Specific applications include paper handling, food conveying (FDA approved), and check-weighing.

SEMI-STRETCH BELTS

Also known as semi-elastic belts, were designed for fractional horsepower drives requiring a controlled stretch belt to provide the driving tension, at a specified circumference, when length adjustment or external tensioning is not available. Their major uses are as low-tension drive belts using fixed-center pulleys and as paper transport belts used in multiple sets on a common shaft, with either common take-up or no take-up at all (fixed-centered shafts). These belts are found in business and office machines, currency transports, vacuum transports, instrumentation, disk drives, and film transports

STRETCH BELTS

Also known as elastic belts, (no woven carcass used) find similar applications to those of the semi-stretch types but provide a greater range of elasticity, at a lower tension, per equivalent belt widths. Common applications include light-duty drives, paper, film, and currency transports, vacuum transports, and light-duty conveying.

Drive Considerations

There are a number of factors to be considered before selecting a particular belt style for a specific application. Two of the most important factors to be addressed are the type of drive configuration and the provisions for belt tensioning (or lack thereof). The first thing to look at is the number of belts required to satisfy the application requirements and the overall geometry of the belt path, including sizes and number of pulleys.

Types of Drives:

The next considerations are the allowable space to accommodate belt width and the type of pulley on which the belt will run. Is the pulley face open or are flanges used to retain the guide belts? Are any pulleys crowned for guidance and belt tracking? If so, what type of crowning is being used and how severe is the crown? What is the face width of the open pulleys or what is the dimension between the flanges? These answers are required for proper belt selection.

Not all belts are designed to withstand running against flanges. Most types of flat woven endless belts will track well over a minimum of pulley crowning. If flanges are required, always use straight sides at 90 degrees to pulley face surface and maintain sharp corners, minimizing any rounding which causes the belt to climb the flange.

General Crowning

Circular/radius crowns are preferred over bevels with flats.

For belts up to 3″ wide:

For belts up to 3″ wide:

Unless unusual tracking problems exist, minimum recommended crowning should be chosen, since ideal properties are developed through uniform belt to pulley contact. If an extreme crown is chosen for use with a stable belt, the full belt width will not be able to stretch and conform to the pulley crown, leaving the percentage of the belt width, not the pulley width. Crown choice is primarily affected by belt styles, installation tension and the degree of precision found in the machine drive alignment.

Any adverse conditions which the belt may encounter, such as extreme temperatures, hostile chemical environments or severe abrasion should be considered as should other specific properties required, such as specific belt thickness, anti-static requirements or FDA approval.

Belt Calculations

The length or circumference of a flat belt is measured along its inside surface, or along the surface contacting the pulleys. When drive details are not available, a close determination of the belt path length can be made by using a wire or a steel tape, pulled taut around the pulleys. This measured distance is referred to as the drive circumference. The actual manufactured belt length may vary from the measured distance depending upon the amount of built-in tension or elasticity required for the specific style of belt, and the type of tension or take-up available on the machine.

Two pulleys, Equal Diameters, open drive configuration:

L = πD + 2C

Two pulleys, Unequal Diameters, open drive configuration:

L = 2C +π[(D + d)/2] +[(D – d)2/4C]

Two pulleys, Unequal Diameters, crossed drive configuration:

L = 2C +π[(D + d)/2] + [(D + d)2/4C]

L = Belt Length, inches

C = Centerline Distance, inches (distance between centers of the two pulleys)

D = Outside Diameter of Larger Pulleys

d = Outside Diameter of Smaller Pulleys

π = 3.14159

Belt Tension

Flat endless belts have a maximum operating or working tension equivalent 10% of their breaking or tensile strength. Total tension on a belt should never exceed the operating or working tension.

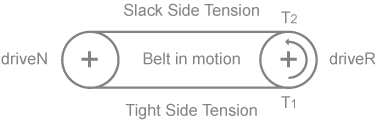

Belts in motion on pulleys develop tight side tension (T1) slack side tension (T2). Tight side tension is created on that section of the belt approaching the driveR pulley. Slack side tension is created on the section of the belt approaching the driveN pulley.

These tensions are illustrated as follows:

Tight side tension plus slack side tension is equal to total tension (TT).

This can be stated as T1 + T2 = TT.

Tension available to do work is stated as effective tension (Te). Effective tension can be found by subtracting slack side tension from tight side tension (Te = T1 – T2) or can be computed using the following formula:

Te (in pounds) = 33,000 X Horsepower (hp)

(Belt speed in feet per minute)

Interested in learning more?

Sign up today for our product courses. We will get back to you shortly.